Solid State Reaction Method For Ceramics Powder Processing

Important methods for solid state materials part 3.

Solid state reaction method for ceramics powder processing. This method gives a good quality of sample and was found to be consistent and simple to synthesize single phase compounds. Solid state reaction the most direct method of making mixed oxides is to react a mixture of metal oxides hydroxides or salts in the solid state. Ceramics prepared by number of synthesis methods such as kumar et al. To obtain for example al 2 mo 3 o 12 from binary oxides it is necessary to have a local 1 3 stoichiometry of al 2 o 3 to moo 3.

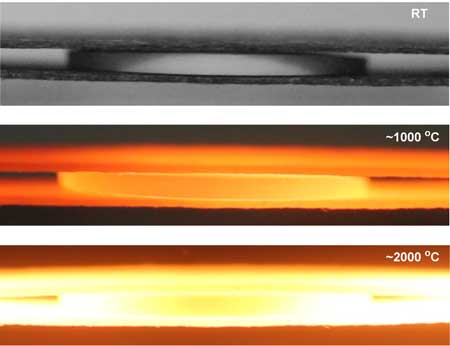

Solid state reaction processing part 2. Fine crystalline batio 3 obtained by reaction between bao and tio 2 in supercritical water at 400 c and 26 mpa had superior properties to the powder obtained by conventional high temperature synthesis in air at 1100 1300 c. Conventional processing to prepare multicomponent mixed oxide ceramic. 1 introduction of solid state synthesis methods part 1.

This book covers both the processing and the synthesis ofceramic. The solid state reaction method or ceramic method is a well known processing route for obtaining thermodynamically stable phases at high temperatures through solid state diffusion. Solid state reaction 3 1. Dielectric properties of bifeo ceramics by.

Studied the ferroelectric properties of bifeo 3 ceramics prepared by solid state reaction method 13. Important methods for solid. Ceramics from solid state reactions part 3. Ceramic powder synthesis and processing are two of the most important technologies in chemical engineering and the ceramics related area of materials science.

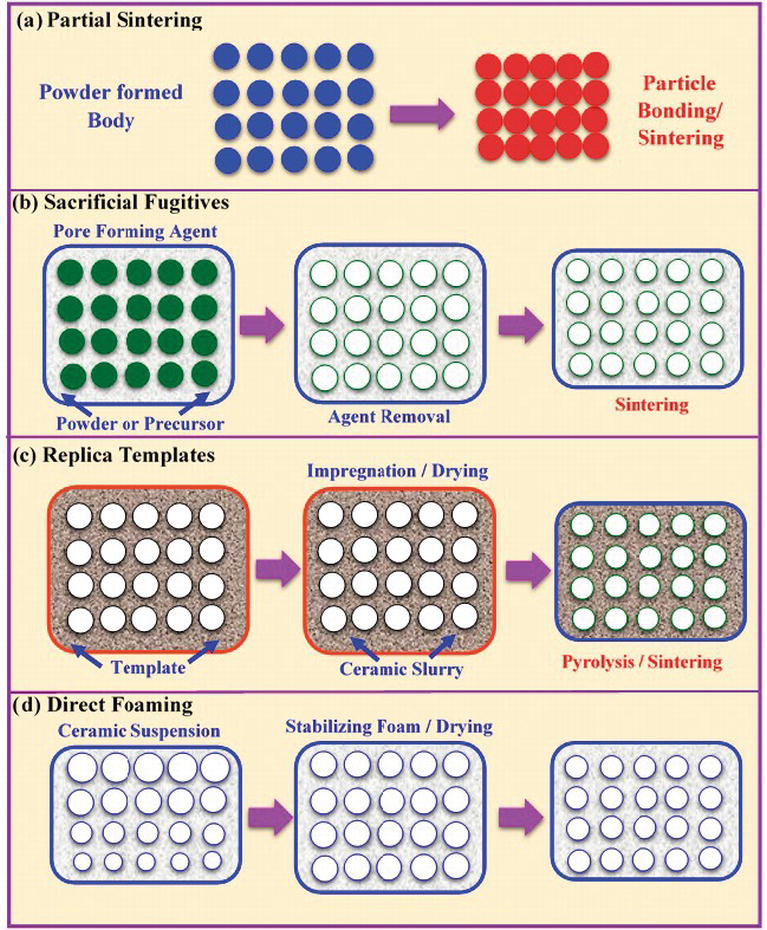

Reference module in materials science and materials engineering 2020. The solid state reaction route is the most widely used method for the preparation of polycrystalline solids from a mixture of solid starting materials. Batio 3 powders synthesized by two different methods based on the solid state mechanism of formation were studied as raw materials for ferroelectric ceramics production. Can be applied in the process.

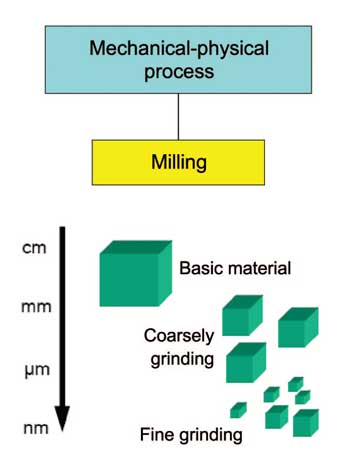

Batching this part of the process can also be known as blending which calculates amounts weighing and initial blended of the raw materials for consistent material flow into a pub mill hopper vibratory feeders can be applied in the process.