Solid Laminated Fiberglass Transom

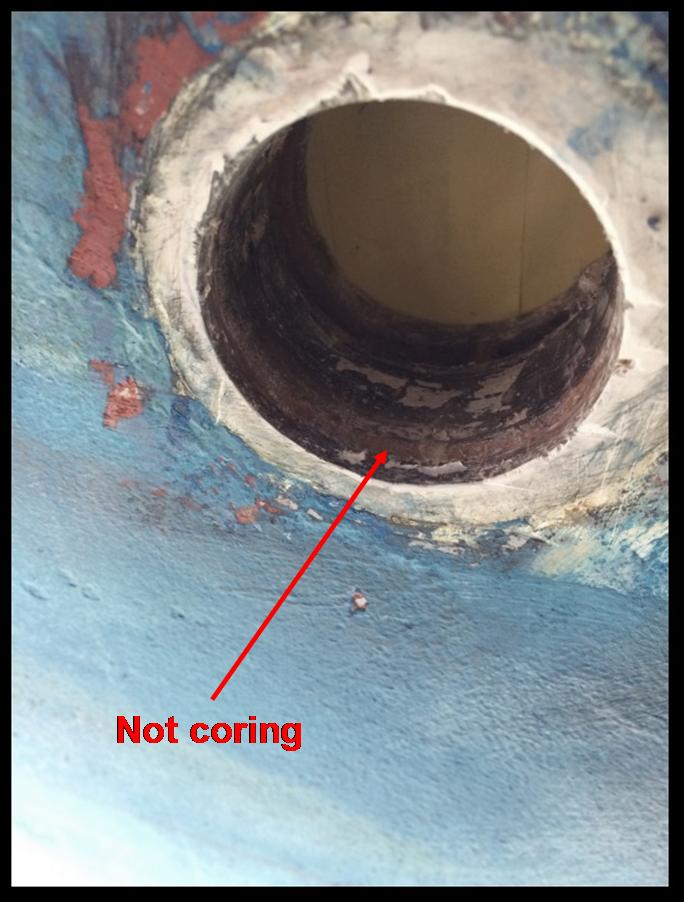

This hole has a risk factor similar to example 1 that is low risk below the waterline.

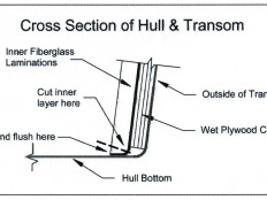

Solid laminated fiberglass transom. I walk around the boat and tap different areas key areas like the transom and i listen carefully says perette. A wooden core was laminated to the inside of the fiberglass transom skin and a new build up of fiberglass was then laminated onto the wooden core. 24 hours later the transom blank is now solid. 1 thick solid wood stile and rail construction.

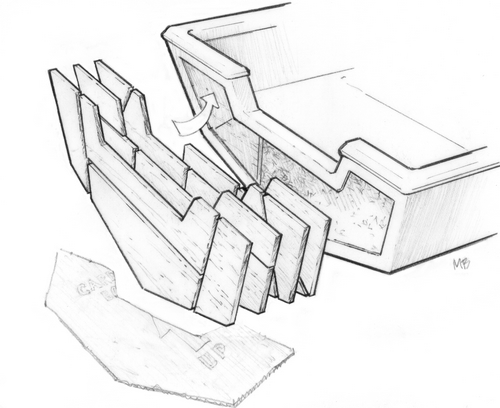

This is a two step process. There is no access to the backside of the hole. This process layering fiberglass then wood then fiberglass is known as sandwich construction. Transoms not only support the weight of the motor they maintain the shape of the boat they are a mounting point for holdowns towing eyes and other accessories.

We laminate thru an open molding process. Your hull deck hatches and console are built from the outside in. Transoms can be produced as slab only or framed with a jamb made as fixed units or hinged to tip up or out. He uses the hammer to perform a simple tap test on the laminate in question.

By glass clown boats. Lamination is a term used for hand laying multiple layers of fiberglass material in a mold. Clear tempered glass is standard. Some boats have splashwells molded in that necessitate separating the hull and deck.

After cleaning up the squeezed out epoxy along the edges with. Transoms are major structural parts of fiberglass powerboats especially outboards. And they must be able to let water out of the hull without letting it back in. Some have curved transoms that require the new core to be laminated to the curvature of the boat.

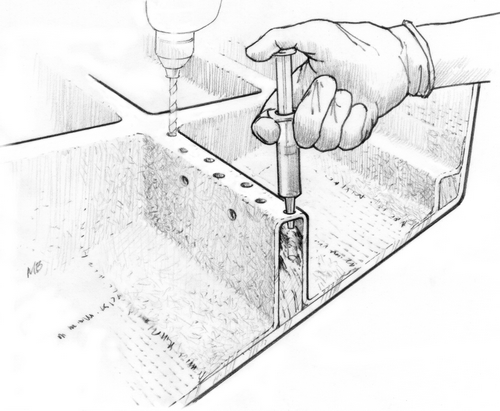

Beveled glass glue chip acid etched and stained glass are all available options. A dry core with a solid laminate gives off a clean crisp sound when you tap it. The overlaps are im portant they create small l or i beams that stiffen the boat and increase bonding area. How to laminate 3 4 ply transom everybody here uses an adhesive known as peanut butter it is resin with cabosil and chopped fiberglass fibers mixed to the consistency of peanut butter.

It is low risk because the hole is deep and there is a lot of surface for the plug to bond to. The transom has a fiberglass skin on both sides of a 2 thick plywood core. I m listening for contrasting sounds. Our boats are 100 composite made of fiberglass resin and high density foam transoms and foam core.

Once mixed you trowel it on to a uniform thickness and clamp the pieces together.